Learn my little processor

Over in my projects list, I have a Starship build.

This madly over-complicated affair has a navigation console that lowers across the bed using a 12v, 100mm linear actuator.

I needed some way of reversing this actuator if it encounters an obstacle.

There are already finger-trap sensors on the hinges that operate the reversing relays, but this circuit here was to protect the lowering of the console in general.

The console itself is controlled by a selection of relays. One of these relays is a dual coil latching type.

These coils are triggered by simple illuminated push buttons supplying 12v. One coil is for open and one coil is for closed.

Therefore, any safety detectors simply have to apply a 12v pulse to the 'open' coil.

This madly over-complicated affair has a navigation console that lowers across the bed using a 12v, 100mm linear actuator.

I needed some way of reversing this actuator if it encounters an obstacle.

There are already finger-trap sensors on the hinges that operate the reversing relays, but this circuit here was to protect the lowering of the console in general.

The console itself is controlled by a selection of relays. One of these relays is a dual coil latching type.

These coils are triggered by simple illuminated push buttons supplying 12v. One coil is for open and one coil is for closed.

Therefore, any safety detectors simply have to apply a 12v pulse to the 'open' coil.

|

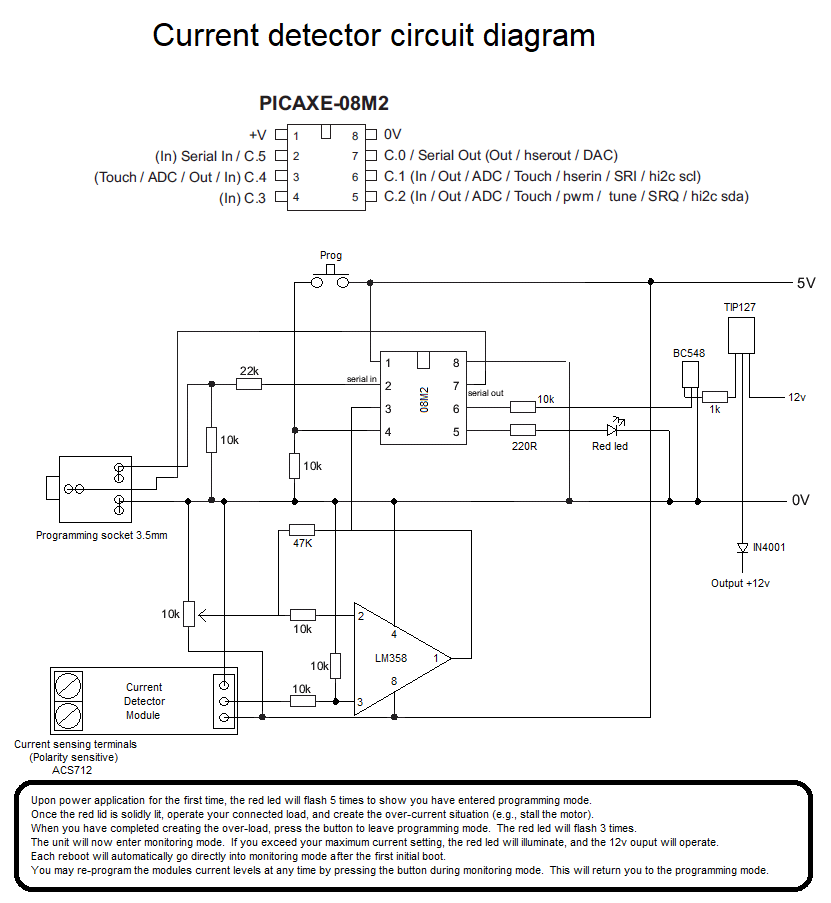

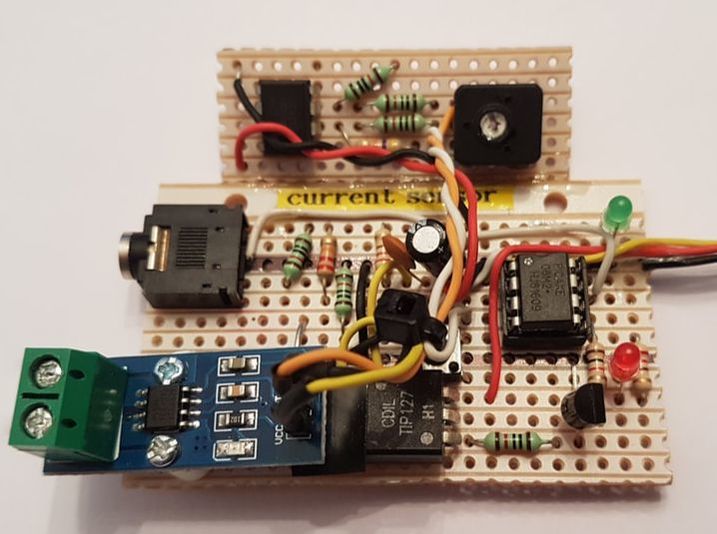

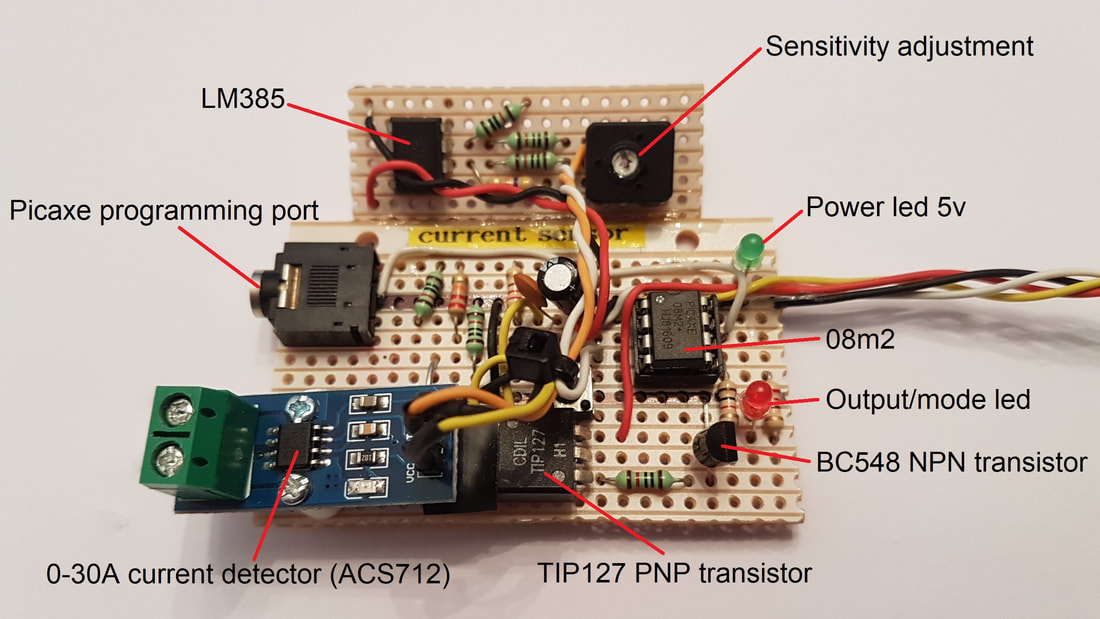

I thought I would use an 08m2 Picaxe chip, as it is a very basic circuit really. A long while ago, I purchased a current detector module from China for about £1.50. It is based on the ACS712 hall effect sensor. You basically apply 5v, and it issues an analogue signal depending on the current passing through the terminals. This particular module is a 0-30A detector. Far too high for my needs, but all I had to hand. My actuator appears to pull a maximum of about 2.88A when not obstructed. So, the circuit to the left is the final layout. Nothing special really. The output is a BC548 triggering a TIP127 to switch 12v to my 'open' relay. There is a simple PCB mount 'prog' button and an output led. After the initial test, it soon became apparent that the module wasn't providing enough signal for the Picaxe to detect on its ADC input pin. I could have re-written the code and used ReadADC10 (0-1024) instead of the lower accuracy ReadADC (0-255), but I tried a different approach. |

|

WARNING. Stripboard bodge alert!

After a poke around my workshop, I found an old LM358 amplifier. I made up a simple circuit to boost the incoming signal. The 10k pot allows adjustment so that the motor 'running' signal is nicely in the middle of the Picaxe's detection range. The code itself is not pretty. My bad! There will be coders out there picking holes in it I am sure. It basically fires up and checks EEPROM address 0 to see if the program has ever run before. It is hasn't, then it enters programming mode immediately. This flashes the red led 5 times. |

It then leaves the red led on while it 'learns' the outer ranges of the current load its is detecting. So now is the time to run the motor and obstruct it, therefore creating load (and raised current).

When you are happy it has learnt enough, press the PCB button and it exits learn mode.

It then will immediately enter monitoring mode from each subsequent power-up. if you wish to re-learn the current levels, then press the PCB button either during monitoring, or during power on.

It learns the current both ways (negative and positive swing). Exceeding the values stored always results in the same 12v output, but that allows for the load to be connected through the current detection module either way. It does make a difference which detection terminal has the supply voltage on it.

When you are happy it has learnt enough, press the PCB button and it exits learn mode.

It then will immediately enter monitoring mode from each subsequent power-up. if you wish to re-learn the current levels, then press the PCB button either during monitoring, or during power on.

It learns the current both ways (negative and positive swing). Exceeding the values stored always results in the same 12v output, but that allows for the load to be connected through the current detection module either way. It does make a difference which detection terminal has the supply voltage on it.

|

You could edit the circuit to have dual outputs.

Pin 7 is only being used as the serial out pin, but it does have the ability to be used as an output. You could then simply have a pair of outputs that operate depending on which threshold has been exceeded. I added a stereo 3.5mm programming socket to the PCB. You don't really need to do this once it has been programmed, but I like the ability to simply plug in if I need to edit the code. |

The Picaxe code:

;Console over-amperage draw detector (auto reverse)

;Steve Croot 2018

;08m2

dirsc = %000111 '1=Output 0=input

symbol Transistor = c.1 'Output to trigger the relay (to reverse the motor)

symbol Redled = c.2 'Programming led

symbol Prog = Pinc.3 'Programming button input

symbol Current = c.4 'Input from the current sensor

symbol Motorload = b0 'ADC value from current sensor

symbol Upperlimit = b1 'Stored value from ADC sensor when under load

symbol Lowerlimit = b2 'Stored value from ADC sensor when under load

symbol Counter = b3 'General use variable for led flashing

symbol Firstboot = b4 'If this equals 0, then the code has never run

symbol Currenttotal = w3 'Total of 10x current samples

Upperlimit=170 'Set a default value in case this is the first run

Lowerlimit=120 'Set a default value in case this is the first run

Read 0,Firstboot 'If it retrieves 0, then its the first ever boot of the program

Read 1,Upperlimit 'Get pre-stored detection values

Read 2,Lowerlimit 'Get pre-stored detection values

pause 1000

high Redled

pause 1000

if Prog=0 and Firstboot>0 then 'If the prog button isn't being pressed, then go straight to main loop.

low Redled

goto main_loop

endif

DO WHILE prog = 1 'Wait for button release

LOOP

Upperlimit=0 'Set a default value to start from

Lowerlimit=255 'Set a default value to start from

low Redled

pause 1000

for Counter=1 to 5 'Flash led 5 times to show your in programming mode

high Redled

pause 150

low Redled

pause 150

next

pause 1000

high Redled 'Switch led on and wait for motor start

'--------------------------------------- 'Sample current when closing obstructed

Sample_close_obstructed_loop:

Gosub Sample_current 'Get load reading from detector

if Motorload>Upperlimit then 'Store highest reading

Upperlimit=Motorload

endif

if Motorload<Lowerlimit and Motorload>0 then 'Store lowest reading

Lowerlimit=Motorload

endif

if Prog=0 then 'Wait for button press

goto Sample_close_obstructed_loop

endif

low Redled

write 1,Upperlimit 'Set motor closing upper trigger load point

write 2,Lowerlimit 'Set motor closing lower trigger load point

DO WHILE prog = 1 'Wait for button release

LOOP

pause 2000

for Counter=1 to 3 'Flash led 3 times to show your exiting programming mode

high Redled

pause 150

low Redled

pause 150

next

write 0,1 'Set the first run flag

'___________________________________________________________________________________________________________________

Main_loop:

gosub Sample_current 'Get load reading from detector

if Motorload>Upperlimit then

gosub Reversemotor

endif

if Motorload<Lowerlimit then

gosub Reversemotor

endif

if Prog=1 then 'Wait for button press (to reset the module to default)

write 0,0 'Clear the first run flag

write 1,0 'Clear the limits

write 2,0

RESET

endif

goto main_loop

'___________________________________________________________________________________________________________________

Sample_current:

for Counter=1 to 5 'Flash led 3 times to show your exiting programming mode

pause 100

readadc Current, Motorload 'Get load reading from detector

Currenttotal=Currenttotal+Motorload

next

Motorload=Currenttotal/5

Currenttotal=0

return

'___________________________________________________________________________________________________________________

Reversemotor: 'Trigger the transistor to reverse the motor

high Transistor

high Redled

pause 500

low Transistor

low Redled

return

;Steve Croot 2018

;08m2

dirsc = %000111 '1=Output 0=input

symbol Transistor = c.1 'Output to trigger the relay (to reverse the motor)

symbol Redled = c.2 'Programming led

symbol Prog = Pinc.3 'Programming button input

symbol Current = c.4 'Input from the current sensor

symbol Motorload = b0 'ADC value from current sensor

symbol Upperlimit = b1 'Stored value from ADC sensor when under load

symbol Lowerlimit = b2 'Stored value from ADC sensor when under load

symbol Counter = b3 'General use variable for led flashing

symbol Firstboot = b4 'If this equals 0, then the code has never run

symbol Currenttotal = w3 'Total of 10x current samples

Upperlimit=170 'Set a default value in case this is the first run

Lowerlimit=120 'Set a default value in case this is the first run

Read 0,Firstboot 'If it retrieves 0, then its the first ever boot of the program

Read 1,Upperlimit 'Get pre-stored detection values

Read 2,Lowerlimit 'Get pre-stored detection values

pause 1000

high Redled

pause 1000

if Prog=0 and Firstboot>0 then 'If the prog button isn't being pressed, then go straight to main loop.

low Redled

goto main_loop

endif

DO WHILE prog = 1 'Wait for button release

LOOP

Upperlimit=0 'Set a default value to start from

Lowerlimit=255 'Set a default value to start from

low Redled

pause 1000

for Counter=1 to 5 'Flash led 5 times to show your in programming mode

high Redled

pause 150

low Redled

pause 150

next

pause 1000

high Redled 'Switch led on and wait for motor start

'--------------------------------------- 'Sample current when closing obstructed

Sample_close_obstructed_loop:

Gosub Sample_current 'Get load reading from detector

if Motorload>Upperlimit then 'Store highest reading

Upperlimit=Motorload

endif

if Motorload<Lowerlimit and Motorload>0 then 'Store lowest reading

Lowerlimit=Motorload

endif

if Prog=0 then 'Wait for button press

goto Sample_close_obstructed_loop

endif

low Redled

write 1,Upperlimit 'Set motor closing upper trigger load point

write 2,Lowerlimit 'Set motor closing lower trigger load point

DO WHILE prog = 1 'Wait for button release

LOOP

pause 2000

for Counter=1 to 3 'Flash led 3 times to show your exiting programming mode

high Redled

pause 150

low Redled

pause 150

next

write 0,1 'Set the first run flag

'___________________________________________________________________________________________________________________

Main_loop:

gosub Sample_current 'Get load reading from detector

if Motorload>Upperlimit then

gosub Reversemotor

endif

if Motorload<Lowerlimit then

gosub Reversemotor

endif

if Prog=1 then 'Wait for button press (to reset the module to default)

write 0,0 'Clear the first run flag

write 1,0 'Clear the limits

write 2,0

RESET

endif

goto main_loop

'___________________________________________________________________________________________________________________

Sample_current:

for Counter=1 to 5 'Flash led 3 times to show your exiting programming mode

pause 100

readadc Current, Motorload 'Get load reading from detector

Currenttotal=Currenttotal+Motorload

next

Motorload=Currenttotal/5

Currenttotal=0

return

'___________________________________________________________________________________________________________________

Reversemotor: 'Trigger the transistor to reverse the motor

high Transistor

high Redled

pause 500

low Transistor

low Redled

return